Common Issues With Limit Switches

Limit switches can run into a bunch of common problems that stop them from working right. These issues include actuators that get stuck, the switch not lining up properly. Wiring troubles, wear and tear, and stuff like dust, dirt, or moisture messing things up.

Stuck actuators happen when the part that moves in the switch gets stuck and can't move like it should. Misalignment means the switch isn't set up right, so it doesn't work when it should. Wiring problems can make the connections bad, so the signals don't go through properly. Mechanical wear is when the switch gets less accurate over time because of all the use. And stuff in the environment, like dust, dirt, or wetness, can mess with how the limit switch works.

Understanding Limit Switches

Limit switches are tools that figure out if something is there or not within a specific area. They have a part that moves when it touches something. When this part moves, it makes the switch change and sends a message to a control system. People often use limit switches in factories to control machines and equipment.

Knowing how limit switches work and what parts they have is important to fix any problems that might pop up. Now, let's take a closer look at how limit switches do their job and what they're made of.

Common Limit Switch Issues

Limit switches can run into some common issues that mess up how they work. These problems include actuators getting stuck, the switch not lining up right, wiring troubles, wear and tear, and things like dust, dirt, or wetness causing trouble.

Stuck actuators happen when the moving part can't move or gets stuck. Misalignment means the switch isn't set up right, so it doesn't work when it should. Wiring problems can make the connections bad, so the signals don't go through right. Mechanical wear is when the switch doesn't work as well over time because it's been used a lot. And things in the environment, like dust, dirt, or wetness, can damage the switch.

It's important to deal with these problems quickly so your limit switches keep working smoothly.

1. Stuck Actuator:

A problem that often happens with limit switches is when the moving part, called the actuator, gets stuck. This means the actuator can't move or is trapped in one spot. When this occurs, the switch can't work properly to figure out if something is there or not.

2. Misalignment:

Another issue that often causes trouble with limit switches is misalignment. This means the switch isn't lined up the right way, so it doesn't work when it's supposed to. This can make it not accurately detect if something is there or not.

3. Wiring Problems:

Wiring problems often give trouble with limit switches. These problems can make the connections bad and mess up how the signal goes through. If you're having wiring problems, it's important to look closely at the wires and make sure they're connected well. Check for any wires that are loose or broken, as they can cause the problem. Also, see if the wires are set up right and not squeezed or damaged in any way. Fixing wiring problems can make your limit switches work better and more reliably.

4. Mechanical Wear:

Another common problem with limit switches is called "mechanical wear." This happens when the parts of the limit switch start to get old and not work as well. It can make the switch less accurate and not do its job right. This wear and tear can happen because the switch has been used a lot, or because things rub together, or because it hasn't been taken care of properly.

5. Environmental Factors:

The environment where limit switches are placed can cause problems. Things like dust, dirt, or wetness can really affect how they work. Dust and dirt can build up on the switch and block it or stop it from moving properly. Wetness can make the electrical parts get rusty and broken, which can mess up how the switch connects or sends signals.

Troubleshooting Limit Switch Issues

Now that we've talked about the problems and how limit switches work, it's time to figure out how to fix those problems. In this part, we'll give you simple steps to find out what's wrong with your limit switches and how to make them work better. We'll show you how to look closely at the switch, check the wires, and do all the steps to fix it. When you finish this part, you'll know what to do to make your limit switches work well and get your projects back on the right track. So, let's begin!

1. Visual Inspection:

When you're trying to figure out what's wrong with your limit switch, start by looking at it closely. Check out the switch itself and the area around it. See if anything seems broken or not connected right. Also, look for stuff that shouldn't be there, like things that might be blocking the switch from moving. Examine the wires too, to see if they look old or damaged.

By doing this careful look, you might find simple fixes for the limit switch problems, which will save you time and make things less frustrating. Don't forget to write down what you see and notice because it can help you later when you're trying to fix the problem. Now, let's move on to the next step and keep working on solving the issues with your limit switch.

2. Actuator Testing:

Now that you've taken out the broken switch and put in a new one that works, it's time to test the part called the actuator. This is an important step in fixing limit switch problems because it helps make sure the new switch works fine.

To test the actuator, you can move it by hand, like you're doing the thing that should make the switch work. Watch to see if the switch reacts the way it should, like opening or closing the circuit. If the actuator doesn't make the switch work, there might be a problem with the wires or how the switch is attached. Testing the actuator is a big part of figuring out what's wrong and making sure the limit switch works fine.

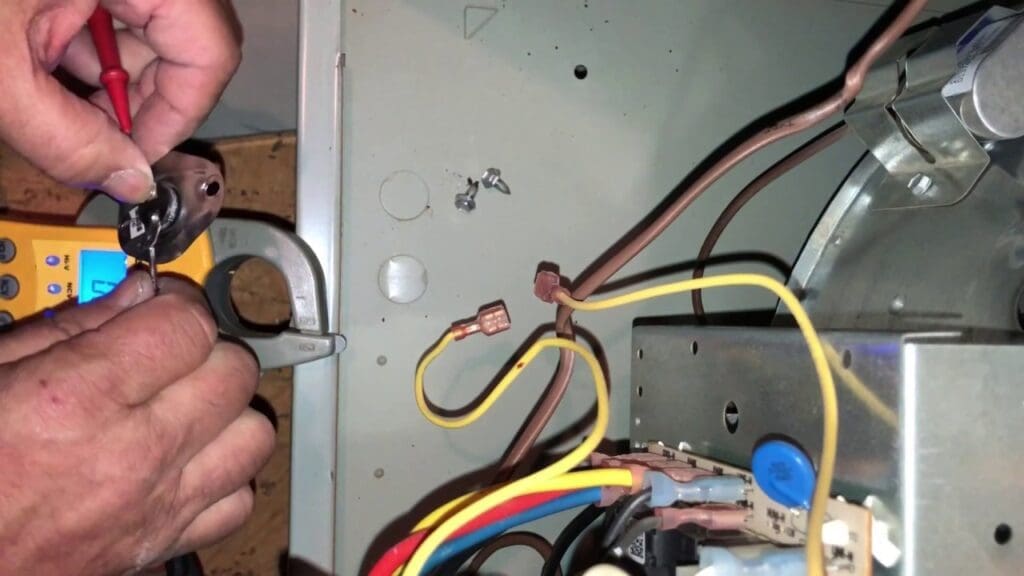

3. Electrical Testing:

Checking the electricity is a very important part of fixing limit switch problems. This helps make sure the new switch is working the right way. To do this, you can use a tool called a multimeter to measure the electricity passing through the switch.

By comparing the measurements you get to what the maker of the switch says, you can see if the switch is doing its job as it should. If the measurements don't look right, it might mean the switch is bad or there's a problem with the wires. Checking the electricity helps you find out if your limit switch is healthy and if there are any issues that need to be fixed.

4. Environmental Considerations:

When you're trying to fix limit switch problems, it's smart to think about the environment where the switch is used. Things like how hot or cold it is, how wet or dry, and how much dust there is can affect how well the switch works and how long it lasts.

So, when you pick a switch, make sure it's designed to handle the specific conditions where it will be working. For example, if your project is in a place with lots of dust or humidity, use a switch that's sealed or has a special rating like "IP" to protect it.

5. Replacing Faulty Limit Switches

Getting rid of a bad limit switch is a really important part of fixing limit switch problems. Once you know what's wrong and you've taken out the old, broken switch, it's time to put in a new one. When you choose a new switch, make sure it's got the right voltage and current rating, the right type, and fits the right way in the place where it goes. After you pick the right replacement, connect it with the wires and put it in the right spot.

6. Power Off:

To stay safe while you're figuring out what's wrong with your limit switch, it's really important to turn off the power to your equipment. This helps make sure you don't accidentally get a shock or harm the equipment you're working on.

7. Remove the Defective Switch:

If your limit switch is giving you problems, it's time to kick it out and put in a new one. The first thing to do when you're trying to fix limit switch problems is to get rid of the bad switch. Don't worry, it's not too tricky. With a few basic tools and some patience, you can take the broken switch out of where it's placed.

8. Select a Suitable Replacement:

When you're picking a new limit switch to replace the old one, you need to think about a few important things.

- Make sure the new switch can handle the same amount of electricity load as the old one. You do this by matching the voltage and current rating.

- There are different types of switches, like lever, plunger, and roller switches. Choose the one that's right for your project.

- Check that the new switch is the same size and fits the same way as the old one.

9. Wiring and Mounting:

When you're trying to figure out what's wrong with your limit switch, two very important things to do are wiring and mounting.

Wiring is about making sure the new limit switch is connected the right way. You need to follow what the maker of the switch says and check all the connections to be sure they're good.

Mounting is about putting the switch in the right place and making sure it's really secure. You can do this by screwing it onto a surface or using something sticky like adhesive to hold it in place.