What Are The Benefits Of Boilers In Commercial Settings?

Reliability

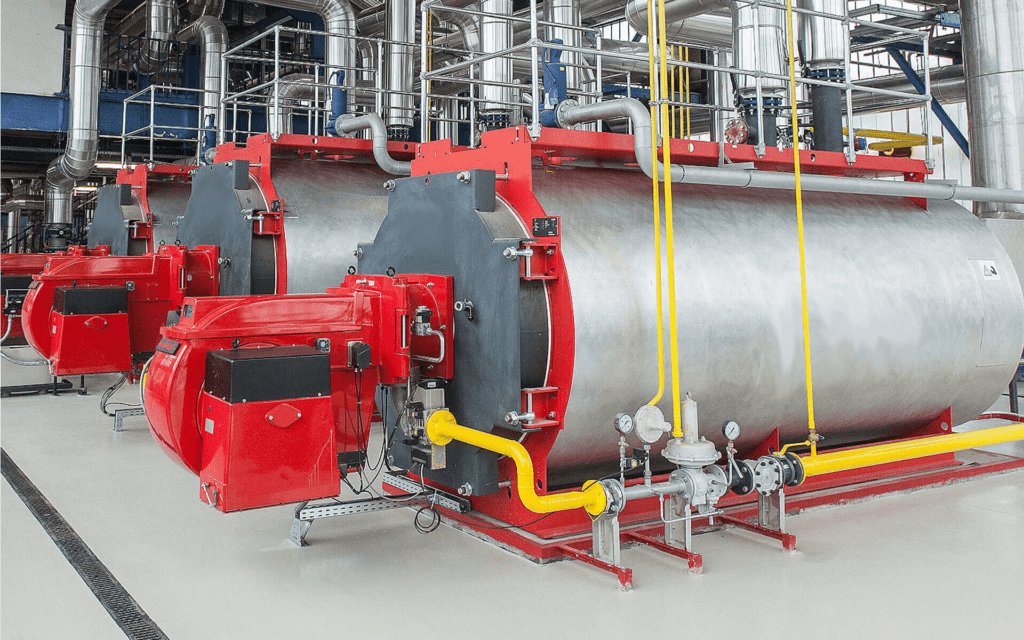

The Importance of Commercial and Industrial Boilers:

Commercial and industrial boilers are like the powerful hearts of many businesses. They provide the heat and steam needed for crucial tasks in different industries. For instance, in factories, boilers help make products by providing heat for machines. In hospitals, they ensure there's hot water for sterilizing equipment. Imagine a big bakery — boilers help bake bread and cakes by providing the right heat. In essence, these boilers are the unsung heroes that keep businesses running smoothly.

These boilers are not just in one specific place; they are found in various industries. Think of a hospital, a large restaurant, or even a school — they all use boilers to keep things running. Picture a chilly winter day; boilers help warm up buildings and make them comfortable. So, whether it's making your favorite snacks, making hospitals and you warm in winter. Commercial and industrial boilers are making our lives better and more convenient.

Environmentally Friendly Practices:

Let's talk about how these boilers can save businesses money. You see, boilers can be very efficient, like a car that doesn't use too much fuel. Efficient boilers use less energy to do their job. And, that's great for businesses because it means lower energy bills. It's like paying less for your electricity or gas at home, but on a bigger scale.

Now, imagine a factory that makes things. If they have an old, not-so-efficient boiler, it will use a lot of energy, and the bills will be high. But if they switch to a newer, efficient boiler, they'll use less energy, and their bills will be lower. So, not only are these boilers good for the environment, but they're also good for a business's wallet. It's like having a double win – saving money and being kind to the planet.

Food Processing Industry

The food industry relies on commercial boilers to fulfill its production requirements. Boilers are essential for various processes, such as cooking, boiling, sterilizing, and drying. These machines ensure food safety, efficiency, and consistency in the production process.

In the food processing industry, boilers are essential in large-scale facilities. Like meat processing plants, dairy factories, beverage production, and baking. They provide the heat and steam needed to cook and process raw ingredients. Sterilize equipment, and maintain hygiene standards. Boilers are vital in food processing, ensuring precise temperatures and energy efficiency. This saves costs and reduces production time. It also helps businesses meet demand while delivering high-quality products. Boilers in the food processing industry contribute to sustainability efforts. Boilers can use eco-friendly sources like biomass or recover waste heat, promoting sustainability. Businesses can reduce their environmental impact and work towards a greener future.

Breweries

Breweries need boilers to make their tasty beers. Boilers give the heat and steam needed for brewing, fermenting, and storing beer. They help keep the right temperatures, making sure the beer tastes the same every time. Boilers are super useful in breweries. They heat water and make steam for boiling ingredients. Also, keep the fermentation temperature right. Boilers also clean the equipment, keeping the brewing process safe and clean.

Boilers in breweries save energy and money. They use energy well and can use eco-friendly sources like biomass or waste heat. This helps the environment and cuts down on costs. In short, boilers are vital for breweries. They provide heat, and steam, and save energy. It also helps breweries make great beer while being eco-friendly.

Textile Industry

Textile factories need boilers for their production. They provide heat and steam for dyeing, bleaching, printing, and fabric finishing. In textile factories, boilers keep the right temperature for dyeing and printing. They are crucial for fabric finishing, helping with treatments like coating and shrinkage. Boilers help textile companies save money by using energy well. They can also use eco-friendly sources like biomass or waste heat. This helps the environment and reduces costs. They are vital in the textile industry. They make textile production efficient, and eco-friendly and ensure high-quality products for customers.

Power Generation

Power plants need boilers to make electricity. Boilers produce steam, which drives turbines to generate electricity. They handle high pressure and heat for efficient energy conversion. These boilers offer reliable energy, meeting electricity needs. Power plants have the flexibility to use different fuels. Such as coal, natural gas, biomass, or waste materials. This versatility helps meet energy demands efficiently. Modern power generation boilers are eco-friendly. Advanced technology reduces emissions and helps the environment. Boilers are vital for a steady electricity supply to homes, businesses, and industries. With better technology, the industry can meet energy demands and be greener.

Chemical Manufacturing

Chemical manufacturing relies on boilers for essential processes. Boilers provide heat and steam for reactions, distillation, and drying in making chemicals. These boilers handle high temperatures and pressures, ensuring precise control over chemical reactions. This results in higher quality products. They're also energy-efficient, saving costs for manufacturers and reducing waste. Boilers in chemical manufacturing promote safety. They provide reliable heat, ensuring safe processes. They play a vital role in chemical manufacturing. They optimize processes, maintain product quality, and support sustainable practices in the industry.

Pulp and Paper Industry

Boilers are essential in the pulp and paper industry. They provide heat and steam for operations like pulping, drying, and papermaking. In large-scale facilities, boilers convert raw materials into pulp and paper. They cook wood chips, break them into fibers, and aid in removing impurities. Boilers also help in the drying process by evaporating moisture from the paper.

These boilers ensure efficient energy use, saving costs and reducing waste. Using sources like biomass or waste heat recovery. The industry can be more environmentally friendly.

In summary, boilers are crucial in the pulp and paper industry. They enable efficient and sustainable production while upholding product quality.

Oil Refineries

Boilers are vital, providing heat and steam for processes like distillation and cracking. In refineries, boilers heat crude oil, separating it into different components. This separation leads to products like gasoline, diesel, and jet fuel. These boilers ensure efficient energy use, reducing waste and costs. They also enhance safety by controlling temperature and pressure during refining. By using eco-friendly sources like natural gas or waste heat recovery. Refineries can reduce their environmental impact. Boilers are crucial in oil refineries, enabling efficient, safe operations. And, the production of various refined petroleum products.

Greenhouses

Boilers are essential in greenhouses, creating the right environment for plants to grow. They maintain precise temperature and humidity. And, ensure ideal conditions for various crops and flowers. Boilers offer flexibility, providing consistent heat in cold weather and steam for humidification. Using efficient techniques and renewable sources. Like biomass or waste heat recovery, greenhouses reduce their environmental impact.

In summary, boilers are crucial for greenhouses. They support optimal plant growth and sustainable farming practices.